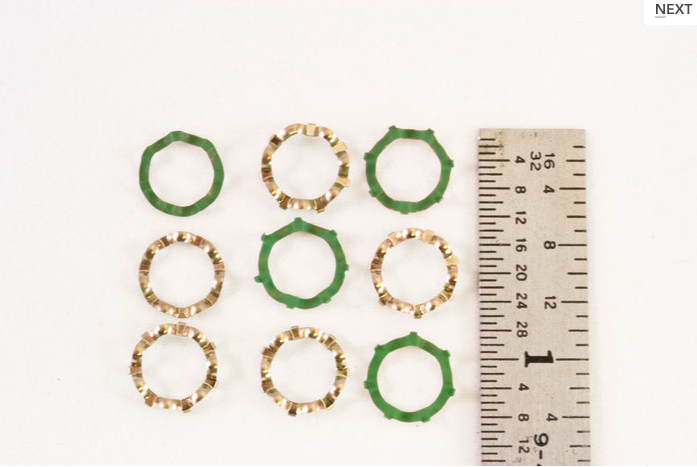

Miniature Parts Coating

|

垫片小零件特氟龙喷涂涂料 No matter how small or delicate the part, Best Fluoro's staff, with decades of experience, can apply Teflon® PTFE coating, chemical resistant coating, corrosion resistant coating, dry film lubricant or a coating that will provide the functional characteristics your miniature part needs. We pay particular attention to the handling of miniature parts and have ultrasonic degreasers and micro blasting equipment to clean and prepare the tiniest of parts for coating. Then, we have many coating stations with microscopes and vision aids so our staff can fixture and coat parts that require tweezers to handles. After coating, and before the curing of the coating, Best Fluoro has developed many in-house techniques to non-contact measure the coated parts to verify that the coating is exactly in specifications. This critical step allows the coating to be verified as to the quality before final curing. This is crucial for miniature parts as the low-mass parts can easily be distorted or destroyed by coating removal after the coating is cured. We then use laser micrometers and other non-contact measuring devices, digital and analog microscopes, and a host of in-house techniques to verify the final quality of the coated parts, before packaging for shipment. |